Air Cooled Screw Chiller

|

|

|

|

Air cooled screw chiller |

||

| A air-cooling system assures the stable supply of cold water. The system functions well in commercial applications such as the cooling of production process lines in manufacturing plants, as well as in air conditioning. Hitachi's A-Series Aircooled chillers comes with Eco-friendly R- 407c refrigerant able to delivery exellent perfomance at high ambient temperature condition. |

Product features and Benefits :

| Feature | Benefits |

|---|---|

| High Performance Screw Compressor | Energy Saving with High Efficiency |

| Continuous Capacity Control | Precise Capacity Control & better partload achievement |

|

Simple Structure and High Technology by inhouse manufacturing |

High reliability |

| Modular System | Easy Maintenance and Better Redundancy |

| Safety Devices Equipped as Standard | Protect the unit from abnormal operation for longer life span |

| Cyclone oil seperator | Very less oil carry over to copmpressor |

| Heat recovery | Free of cost Hot water generation |

| High Ambient Type | Works up to 50 Deg C Ambient |

Energy Saving :

| High Performance A-Type Screw Chiller | ||

|---|---|---|

|

This HITACHI A-Series air-cooled water chiller features high efficiency and energy conservation, which is specially developed for various airconditioning systems and industrial refrigeration systems. |

|

|

|

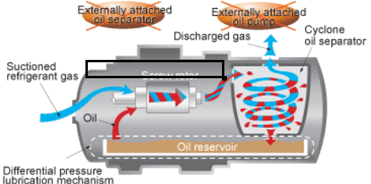

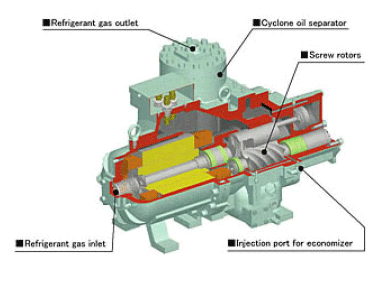

Built-in Cyclone Oil SeparatorLow oil carrying-out is realized and reduction of heat transfer efficiency is minimized. |

||

|

No outside pump is required due to the reliable differential-pressure oil-feeding system. This oil-feeding system, which does not use any electrical mechanism, prevents the compressor from being damaged and maintains long-term stable operation. |

|

|

|

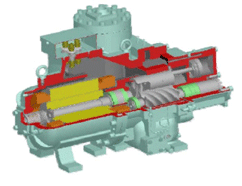

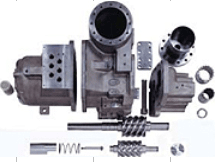

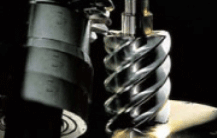

High reliability by inhouse manufacturing of compressors Because all manufacturing processes, from rotor manufacturing to unit assembly, are done internally, exceptional reliability is achieved. |

||

|

Low Vibration, Low Noise Without the conventional demister chamber system, no noise is produced during oil separation of discharge gas. A vibration-proof base is not required for the chiller body thanks to the firmly-secured, lowvibration screw compressor. minimized. |

|

|

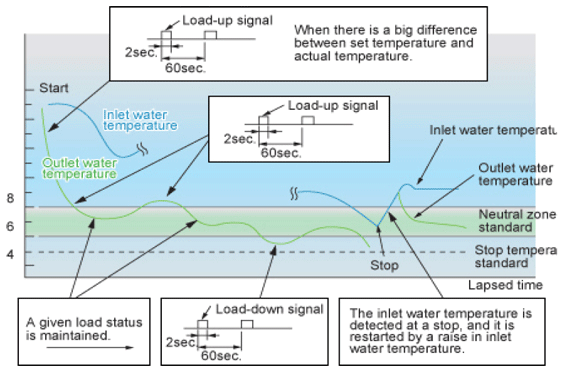

Precise Capacity Control :

| Continuous Capacity Control |

|---|

| The temperature of the chilled water outlet can be kept at the set temperature ±1°C by continuous capacity control, so it is suitable for industrial use. |

|

High Reliability :

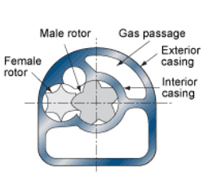

| Simple Structure and Small Number of Parts | |

|---|---|

| Whereas the number of main parts for the casing, compression mechanism and capacity control mechanism of a reciprocating compressor is 268, that of a screw compressor is only 27, just one tenth of the number. A structure with so few parts offers high reliability and easy maintenance. |

|

| Most reliable technology because of inhouse manufacturing of conmpressors | |

| Because all manufacturing processes, from rotor manufacturing to unit assembly, are done internally, exceptional reliability is achieved. |

|

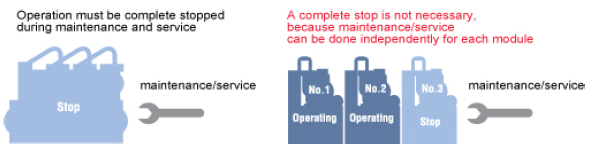

Easy Maintenance :

| Modular System | |

|---|---|

| Hitachi chiller units feature a modularization cycle structure, so each module can be packed and transported individually, for more convenient local installation and displacement. Furthermore, the refrigerant system of each module can be operated independently, which makes maintenance easier. | |

|

|

Compact and Light Weight :

| The Volume, installation space and weight are all reduced, making installation easy. Through combination of screw compressors with low operation noise and vibration, newly shaped fan vanes and DC convertor motors, coupled with acoustic shrouds, less chiller unit operation vibration and noise occur. |

|---|

Safety Devices Equipped as Standard :

| The Hitachi chiller is equipped with several safety devices as standard. Those safety devices protect the unit from abnormal operation for higher reliability and longer lifespan of the chiller. | |

|---|---|

| List of Safety Devices | |

| Three-Phase Over-current Relay | Fusible Plug |

| High-Pressure Switch | Freeze Protection Thermostat |

| Low-Pressure Switch | Reverse Phase Protection Relay |

| Oil Heater | Discharge Gas Thermostat |

| Internal Thermostat for Comoressor Motor | Operation Hour-Meter and Safety Valve |

Air cooled screw chiller with heat recovery option :

| Hitachi Air-cooled screw chiller with heat recovery option is added advantage which can generate hot water upto a max. temperature of 55°C without any increase in operating cost of the chiller. The heat recovery is practically at zero operating cost, alternately meaning a substantial increase in the efficiency of the water chiller. The amount of heat recovery is a direct saving, thus increasing the efficiency considerably. |

|---|

Screw Compressor A-Series :

| High Performance A-Type Screw Chiller | |

|---|---|

|

Wide-range capacity control 1. 15% minimum load operation |

|

|

Cyclone oil separator 1. Ultra-low oil carry-out rate 2. Patented swirl flow oil separation system 3. No mesh wires, no demisters, no filters |

|

|

High performance 1. High precision & high-grade finished screw rotors |

|

|

High reliability 1. Large-capacity triple/double ball bearing 2. High-reliability, two-pole,large-capacity motor ensures low noise,low vibration as well as low speed running. |

|

HITACHI High ambient chiller :

|

This series of HITACHI Air-cooled water chillers up to 310 Tr has been developed for various requriements of Air-conditioning systesm and industrial chilled water system, where these quipment are operated under high ambient temperatures 50 °C, Therefore, the units can be utilizes under wide temperature range. These water chillers are quipped with newly model-changed semi-hermetic HITACHI A-Type screw compressors, featuring high reliability, low noise and low vibration and highly efficient air-cooled condenser resulting in compact design. This unit is composed of compressors, air-cooled condensers, Shell-tube type water cooler, and other auxilary and control devices, compactly pacaked in a weather-proof cabinet which is constucted of galvanized sheet plates processed with specially baked resin paint. |

|

Air Cooled Screw Chiller - Line Up :

| Air Cooled Screw Chiller - Line Up. [ HP ] | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R-407C | 40 | 50 | 60 | 75 | 100 | 120 | 150 | 180 | 200 | 240 | 270 | 300 | 330 | 350 | 360 | 380 | 400 |