|

|

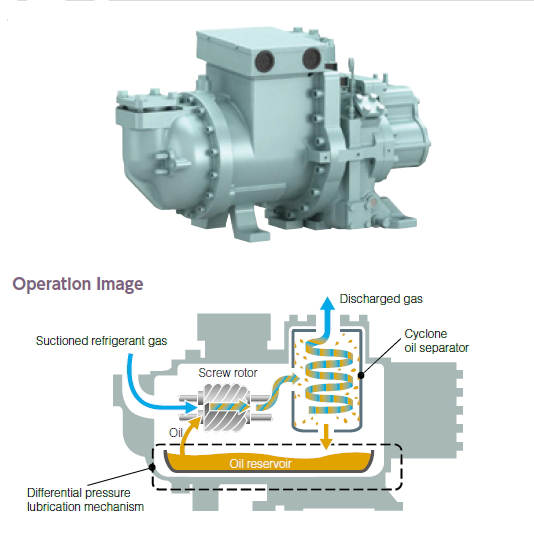

Operating Principle of The Screw Compressor |

|

The refrigerant gas and oil flow into the oil separator together.

The cyclone system begins to separate the refrigerant gas

and oil by centrifugal force. Refrigerant gas is ejected from

the discharge port, and oil drops down to the bottom tank. |

|

Lubrication oil is required for sealing the area between the two

screw rotors as well as for the lubrication of the bearings, but

it decrease the efficiency of air-conditioning units at heat

exchangers. The oil and refrigerant are separated by

centrifugal force in the cyclone oil separator. After it is

compressed by the screw rotors, refrigerant gas enters the

upper side of the separator.

|

|

Refrigerant gas then enters through the lower side of the

separator, and the oil is separated by centrifugal forces to the

wall of the separator. Oil then goes down to the oil tank along

the wall. The oil is accumulated in the oil tank, which is

located on the bottom of the separator, and only refrigerant

gas is discharged from the discharge port, which is located

on the upper side of the separator. The oil that is accumulated

in the tank is then supplied to the screw rotors by pressure

difference. Unlike other compressor structures, this structure

doesn't require mechanical parts such as an oil pump for its

oil supply, which leads to higher reliability for the compressor.

|